Excellent Quality Oxygen-Making Molecular Sieves - Alcohol Dehydration in Distillation Tower/Desiccant/Adsorbent/Hollow glass molecular sieve – AoGe

Excellent Quality Oxygen-Making Molecular Sieves - Alcohol Dehydration in Distillation Tower/Desiccant/Adsorbent/Hollow glass molecular sieve – AoGe Detail:

Zeolite molecular sieves have a unique regular crystal structure, each of which has a pore structure of a certain size and shape, and has a large specific surface area. Most zeolite molecular sieves have strong acid centers on the surface, and there is a strong Coulomb field in the crystal pores for polarization. These characteristics make it an excellent catalyst. Heterogeneous catalytic reactions are carried out on solid catalysts, and the catalytic activity is related to the size of the crystal pores of the catalyst. When a zeolite molecular sieve is used as a catalyst or a catalyst carrier, the progress of the catalytic reaction is controlled by the pore size of the zeolite molecular sieve. The size and shape of the crystal pores and pores can play a selective role in the catalytic reaction. Under general reaction conditions, zeolite molecular sieves play a leading role in the reaction direction and exhibit shape-selective catalytic performance. This performance makes zeolite molecular sieves a new catalytic material with strong vitality.

Technical Data

| Item | Unit | Technical data | |||

| Shape | Sphere | Extrudate | |||

| Dia | mm | 1.7-2.5 | 3-5 | 1/16” | 1/8” |

| Granularity | % | ≥96 | ≥96 | ≥98 | ≥98 |

| Bulk density | g/ml | ≥0.60 | ≥0.60 | ≥0.60 | ≥0.60 |

| Abrasion | % | ≤0.20 | ≤0.20 | ≤0.20 | ≤0.25 |

| Crushing strength | N | ≥40 | ≥60 | ≥40 | ≥70 |

| Static H2O adsorption | % | ≥20 | ≥20 | ≥20 | ≥20 |

Application/Packing

Dehydration of many kinds of liquids(e. g: ethanol)

Drying for air, refrigerant, natural gas and methane

Drying for cracked gas, ethylene, acetylene, propylene and butadiene

Insulating glass desiccant

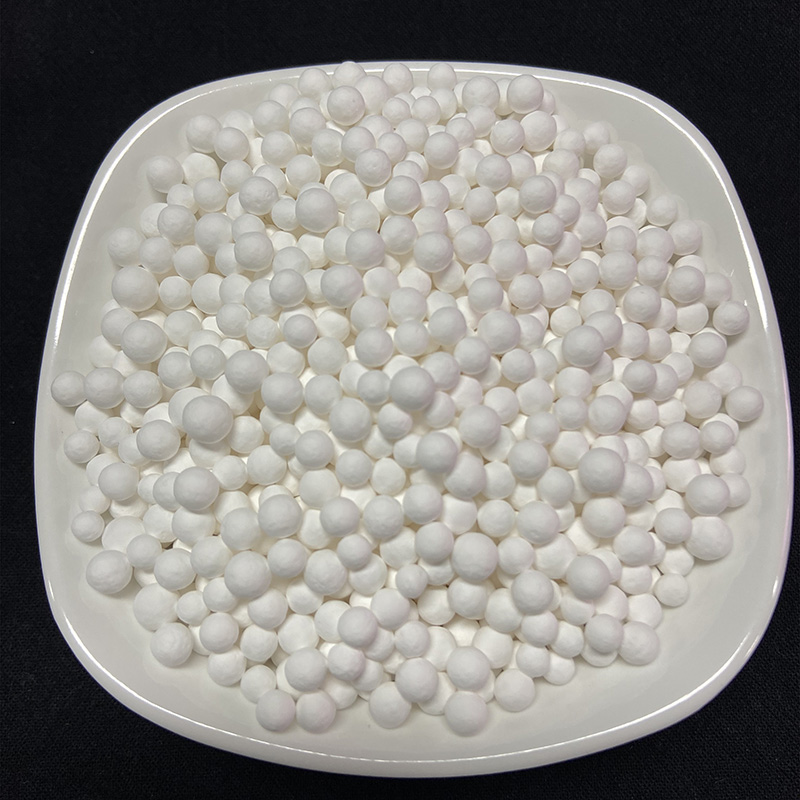

Product detail pictures:

Related Product Guide:

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for Excellent Quality Oxygen-Making Molecular Sieves - Alcohol Dehydration in Distillation Tower/Desiccant/Adsorbent/Hollow glass molecular sieve – AoGe , The product will supply to all over the world, such as: Mombasa, Philippines, Chile, By continuous innovation, we will present you with more valuable items and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.