Factory Outlets For Silica Gel - Blue Silica Gel&White Silica Gel&Orange Silica Gel Color-changing silicone – AoGe

Factory Outlets For Silica Gel - Blue Silica Gel&White Silica Gel&Orange Silica Gel Color-changing silicone – AoGe Detail:

Technical Specifications of Color-changing Blue Glue Indicator

|

PROJECT |

Index |

||

|

Blue glue indicator |

Color changing blue glue |

||

|

Particle size pass rate %≥ |

96 |

90 |

|

|

Adsorption capacity % ≥ |

RH 20% |

8 |

– |

|

RH 35% |

13 |

– |

|

|

RH 50% |

20 |

20 |

|

|

Color rendering |

RH 20% |

Blue or light blue |

– |

|

RH 35% |

Purple or light purple |

– |

|

|

RH 50% |

Light red |

Light purple or light red |

|

|

Heating loss % ≤ |

5 |

||

|

Exterior |

Blue to light blue |

||

|

Note: special requirements according to the agreement |

|||

Instructions For Use

Pay attention to the seal.

Note

This product has a slight drying effect on the skin and eyes, but does not cause burns to the skin and mucous membranes. If accidentally splashed into the eyes, please rinse with plenty of water immediately.

Storage

Should be stored in a ventilated and dry warehouse, sealed and stored to avoid moisture, valid for one year, the best storage temperature, room temperature 25 ℃, relative humidity below 20%.

Packing Specification

25kg, the product is packed in composite plastic woven bag (lined with polyethylene bag to seal). Or use other packaging methods according to customer requirements.

Adsorption Precautions

⒈ When drying and regenerating, attention should be paid to gradually increase the temperature, so as not to cause the colloidal particles to burst due to severe drying and reduce the recovery rate.

⒉ When calcining and regenerating silica gel, too high temperature will cause changes in the pore structure of silica gel, which will obviously reduce its adsorption effect and affect the use value. For blue gel indicator or color-changing silica gel, the temperature of desorption and regeneration should not exceed 120 °C, otherwise the color developing effect will be lost due to the gradual oxidation of the color developer.

3. The regenerated silica gel should generally be sieved to remove fine particles to make the particles uniform.

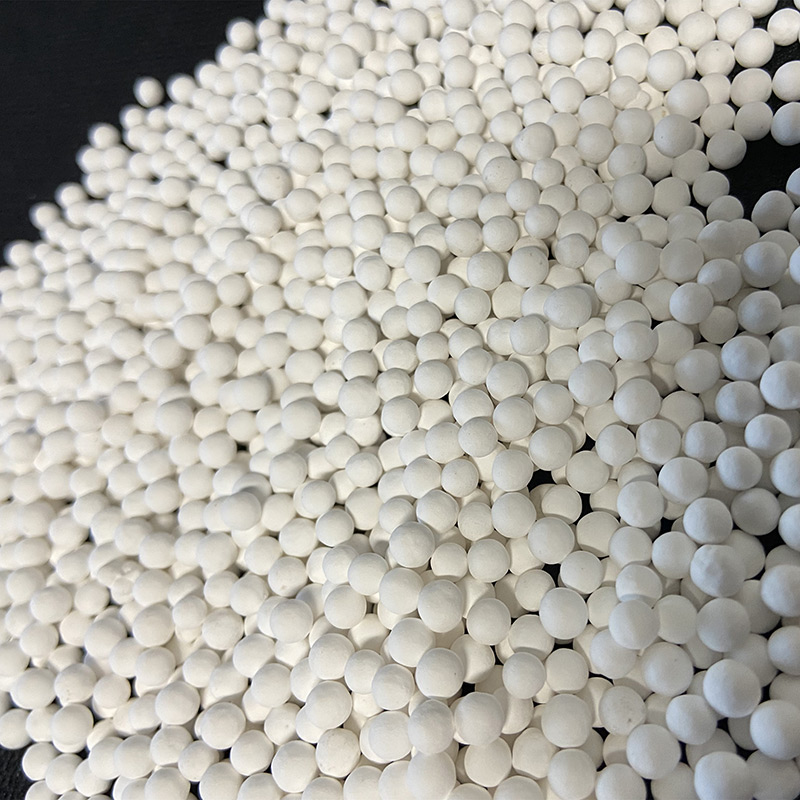

Product detail pictures:

Related Product Guide:

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for Factory Outlets For Silica Gel - Blue Silica Gel&White Silica Gel&Orange Silica Gel Color-changing silicone – AoGe , The product will supply to all over the world, such as: Rotterdam, Australia, Istanbul, Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!